Machining technology is an important part of modern manufacturing and includes a variety of techniques and processes for transforming raw materials into finished products with specific shapes and sizes. With the continuous development of science and technology and the ever-changing market demand, machining technology is also evolving. Understanding and mastering these machining technologies can not only improve productivity, but also improve product quality and accuracy. This article will discuss in detail several common machining technologies, including their principles, applications, advantages and disadvantages and future development trends.

-

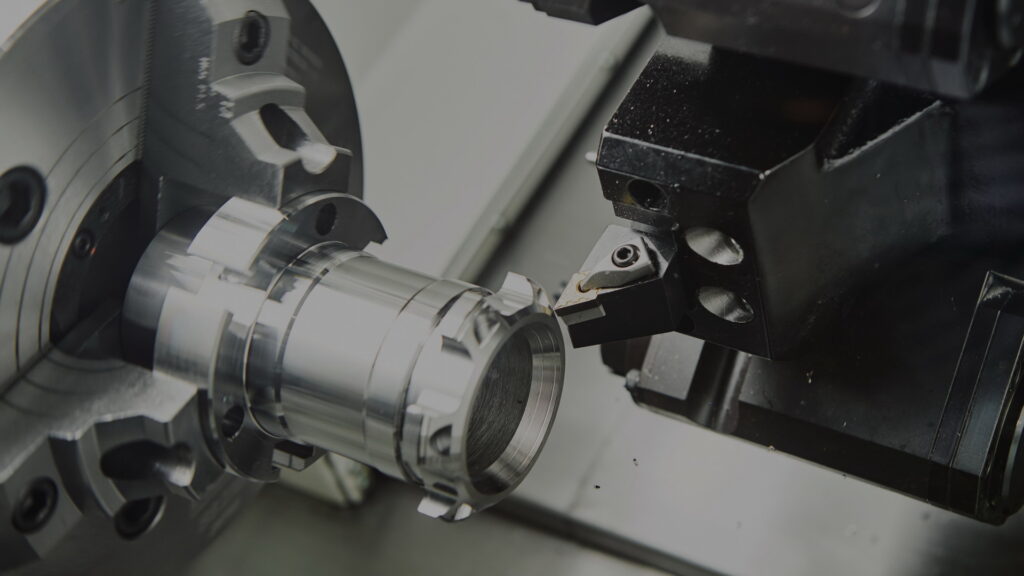

- Turning processing

Turning is the use of lathes to rotate a fixed workpiece, through the cutting movement of the tool to remove excess material, so as to achieve the desired size and shape. In the turning process, the tool mainly cuts by rotation, while the workpiece is fixed. This process is generally used for machining cylindrical or conical parts such as shafts, rings or housings. Commonly turned materials include metals, plastics and some composites.

-

- Milling processing

Milling is the use of a tool on a milling machine to cut a workpiece. Unlike turning, the workpiece in milling is generally fixed, while the tool cuts the material through rotary motion. The process can be used to machine parts of different shapes, such as flat, grooved and curved surfaces, and is widely used in aerospace, automotive and machinery manufacturing.

3.Drilling

Drilling processing is mainly used for drilling holes in workpieces, generally using special drilling machines or CNC machining centres. The process has high precision and is suitable for the processing of various materials. Drilling can be used to make screw holes, pin holes, buried holes and so on. , widely used in machinery, electronic parts, construction and other fields.

-

- Grinding processing

Grinding is a kind of processing method with abrasive as the cutting medium, which is mainly used to improve the surface accuracy and surface quality of the workpiece. In order to achieve a high degree of shape accuracy and surface smoothness, generally used in the later processing of materials. There are many types of cutting machines, mainly surface grinders, cylindrical grinders, internal grinders and so on.

-

- Stamping

Stamping processing is a method of forming and processing materials such as plates, strips or pipes using a stamping machine through punches and moulds. The process is widely used in automobile manufacturing, household appliances, electronic products and engineering machinery, and can mass produce various shapes of parts.

-

- Electrical processing

Electromachining is a non-contact processing method, metal materials are mainly processed in the form of electric spark discharge. The technology can be divided into electric discharge machining. (EDM) and wire cutting processing, widely used in mould manufacturing and precision parts processing.

Translated with DeepL.com (free version)